<del id="qssm2"></del> <ul id="qssm2"></ul> <del id="qssm2"></del>

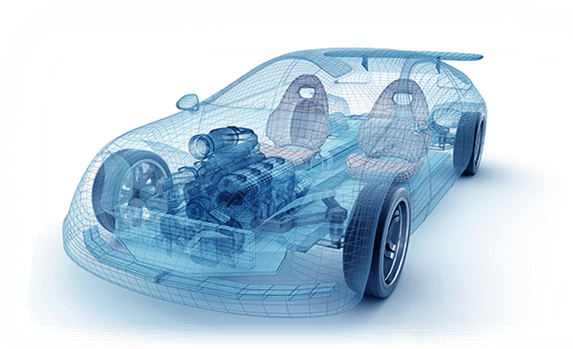

Fully grasp the design and development capabilities of fuel pumps, electronic water pumps, and new energy vehicle cooling systems, and be able to provide customers with efficient, energy-saving, and low-cost solutions

Through independent product research and development, industrial chain integration, and intelligent manufacturing, we achieve a lightweight, low-cost, and cost advantage of over 30% compared to international competitors

Stable operation of high standard quality assurance system: benchmark project, Dongfeng Nissan project, 3MIS market defect 44.6PPM, ranking second among five fuel pump suppliers

The supporting scale of the fuel pump automobile main engine factory is 5 billion yuan/year; The explosive growth of new energy vehicles, with a future supporting scale of 25 billion yuan/year for cooling systems; The total value of the confirmed supporting projects of the automobile group in the bidding is 900 million yuan, with a goal of achieving a market share of over 8% in the oil pump market by 2022.

Fuel pump noise is a pain point for car manufacturers, and bidding can provide silent and efficient fuel pump solutions

Master the core technology of National VI fuel pump

Direct injection technology in the cylinder leads the development direction of automotive engines, and we have successfully developed a high-pressure fuel pump together with the FAW Group Technology Center through bidding

Successfully developed low noise, lightweight, and long-life new energy electric vehicle water pumps to fill the domestic gap

Intelligent electric water pump.

Fully meet customer needs

Design and development are based on local conditions, with faster response and more accurate correspondence

Comprehensive experimental verification ability

Structural Strength Analysis

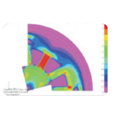

Fluid Analysis

Modulus Analysis

Electro Magnetic Field Analysis

·Routine tests: 55 items

·Loading test: 33 items

·Project matrix test: 414 items

·Basic characteristic test: 7 items

·Loading project test: 18 items

★ Routine tests: 36 items

★ Loading test: 21 items

★ Project matrix test: 125 items

ISO/TS16949

NISSAN ASES

ISO14001

Environmental Management System

IATF16949-2016

·Following the "Three Realism"

·Typical adverse FAT accumulation

·QRQC Action Guidelines

·Market

·3mis 50 PPM

·Zero kilometer 20 PPM

No accepting Defects

No Manufacturing Defects

No Outflow Of Defects

GK Mode & Engineering Supervision

Online monitoring & analysis of process stability

Quick response to quality issues

Scientifically organize and arrange production activities to ensure customer delivery time

·Process Engineering

·Equipment development & preservation

·Injection molding

·CNC

·Stamping

·Assembly of components

·Assembly Assembly

·Packaging

·Assembly Assembly

·Packaging

·Production plan

·Material control

The modular manufacturing workshop represents the most advanced manufacturing concept and highest technological level in the domestic oil pump industry.

Ability to independently design and develop automated equipment and high-precision molds

Production management adopts advanced ERP, MES management system, and intelligent logistics system

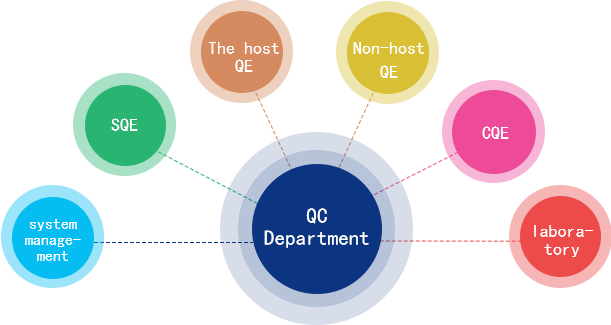

Fully implement Nissan GK model in quality management and pursue a zero defect quality assurance system

National Consultation Hotline

+86-20-86788282<tfoot id="mmkgq"></tfoot>

<strike id="mmkgq"></strike>